BFHP high-performance fiber-reinforced concrete (fiber-reinforced cement + additives)

High-performance fiber concrete

The latest advances in concrete technology have given rise to BFHP (=High-Performance Fiber Concrete).

Cement and admixture dosages combined with very fine fillers give exceptional mechanical properties to these concretes of incomparable aesthetic finesse. We ensure the aesthetic success and solidity of your projects.

Our expertise

- Molding

- Casting

- Color

- Protection

- Transport

Marius Aurenti also offers its own formulas for the creation of highly resistant objects at affordable prices.

Full details in the technical data sheets.

High-performance fiber-reinforced concrete (BFHP)

Marius Aurenti's High-Performance Fiber-Reinforced Concrete (HPFC) is a material of choice for discerning designers seeking a concrete that combines performance and aesthetics. Known for its flexibility and ability to meet the specific needs of decorative pieces, HPFC stands out for its exceptional technical properties. Easy to use, this concrete offers uncompromising strength, allowing craftspeople and designers to realize their most ambitious projects with finesse and durability.

HPFC offers exceptional flexibility for custom object projects, in terms of shape, texture, and color. We collaborate with specialized design firms to develop solutions tailored to specific needs.

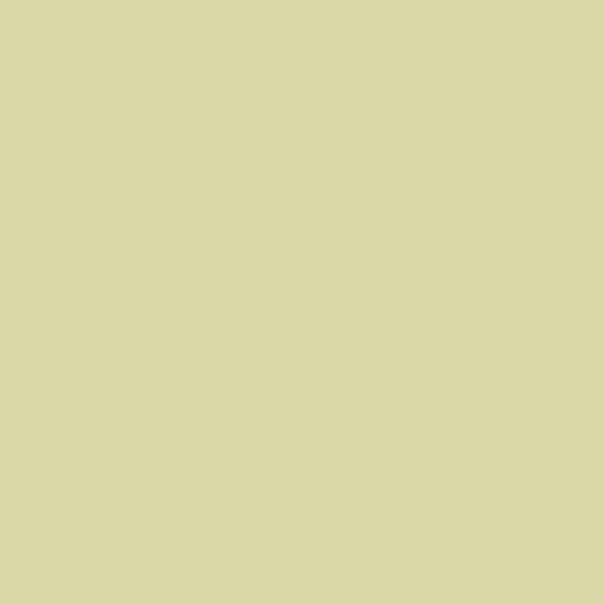

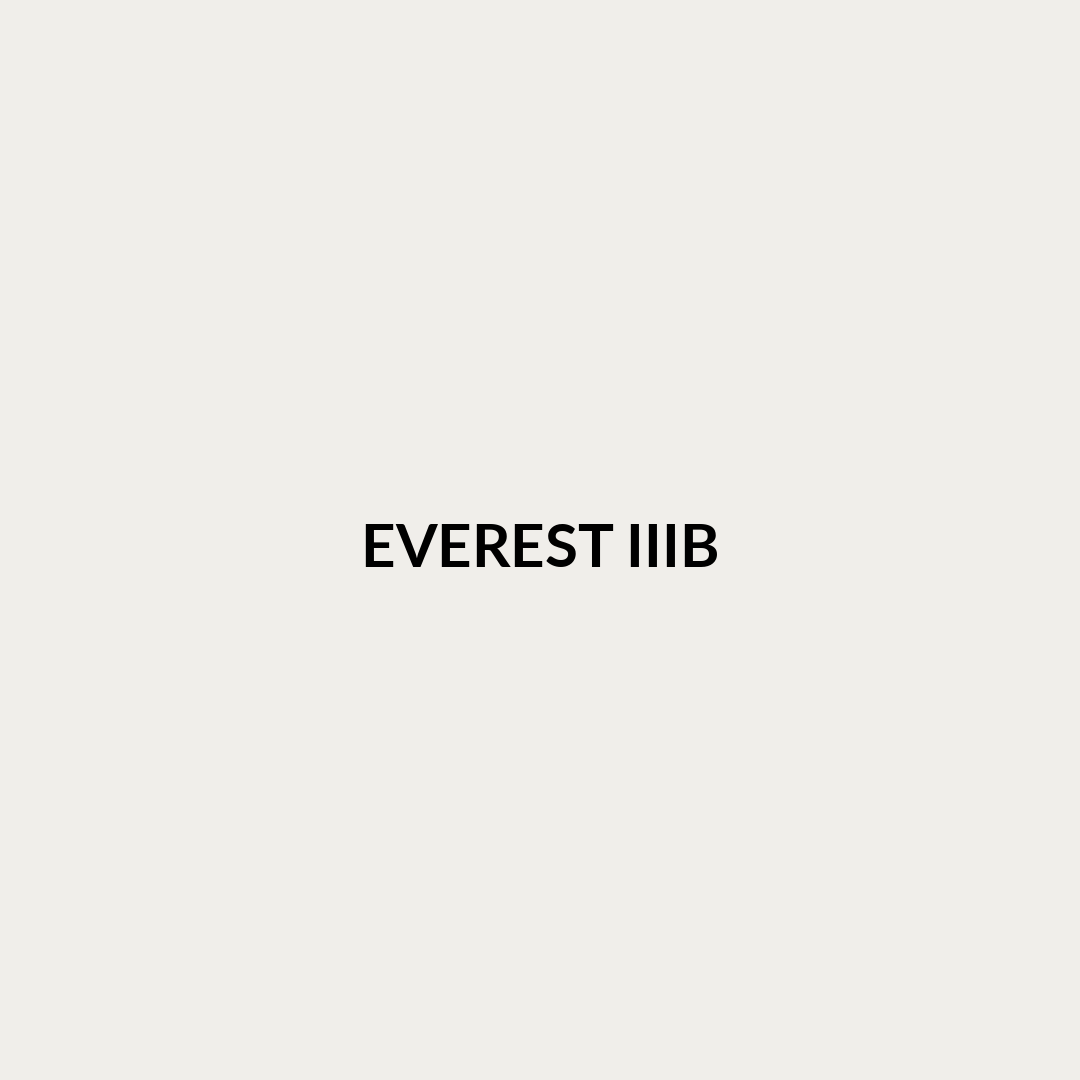

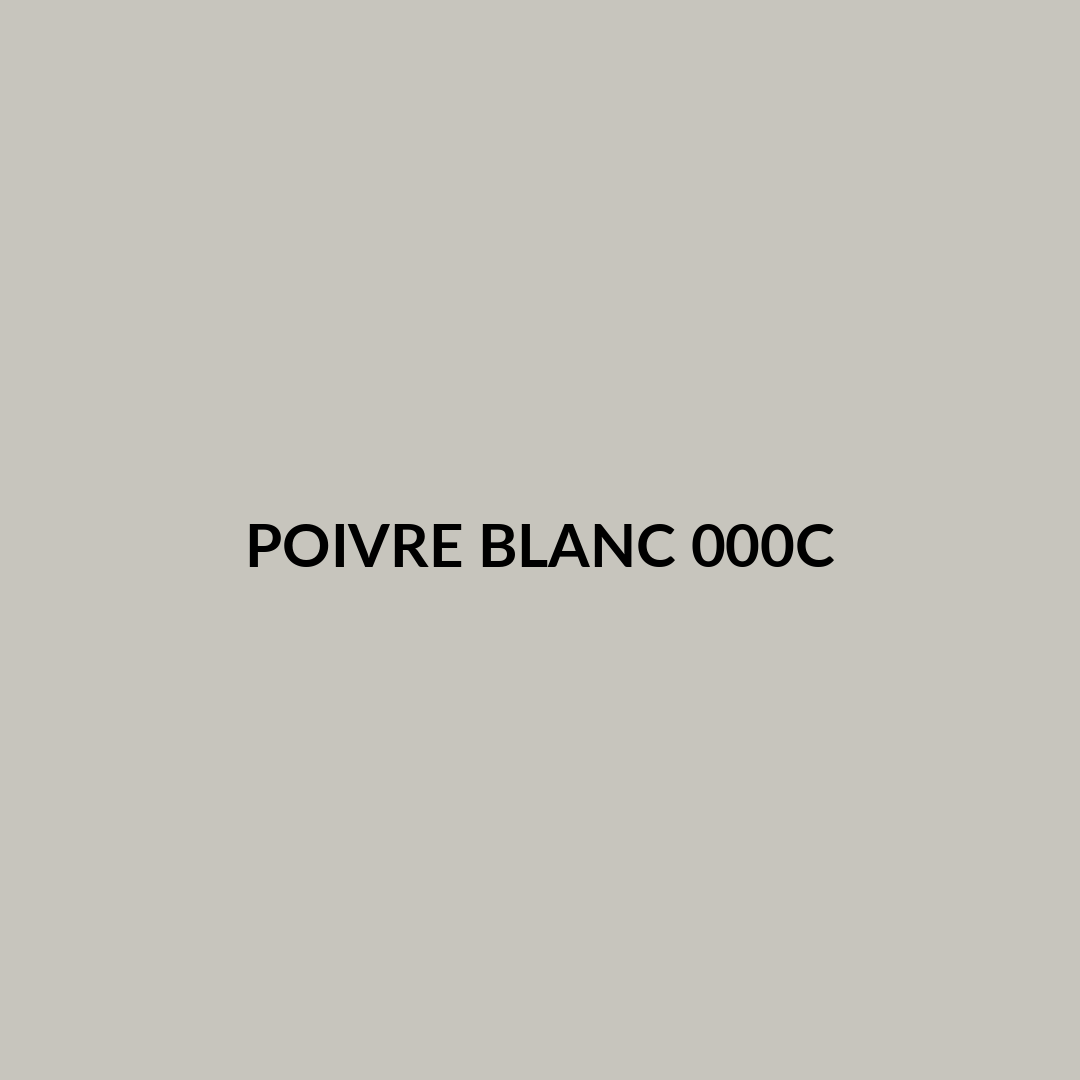

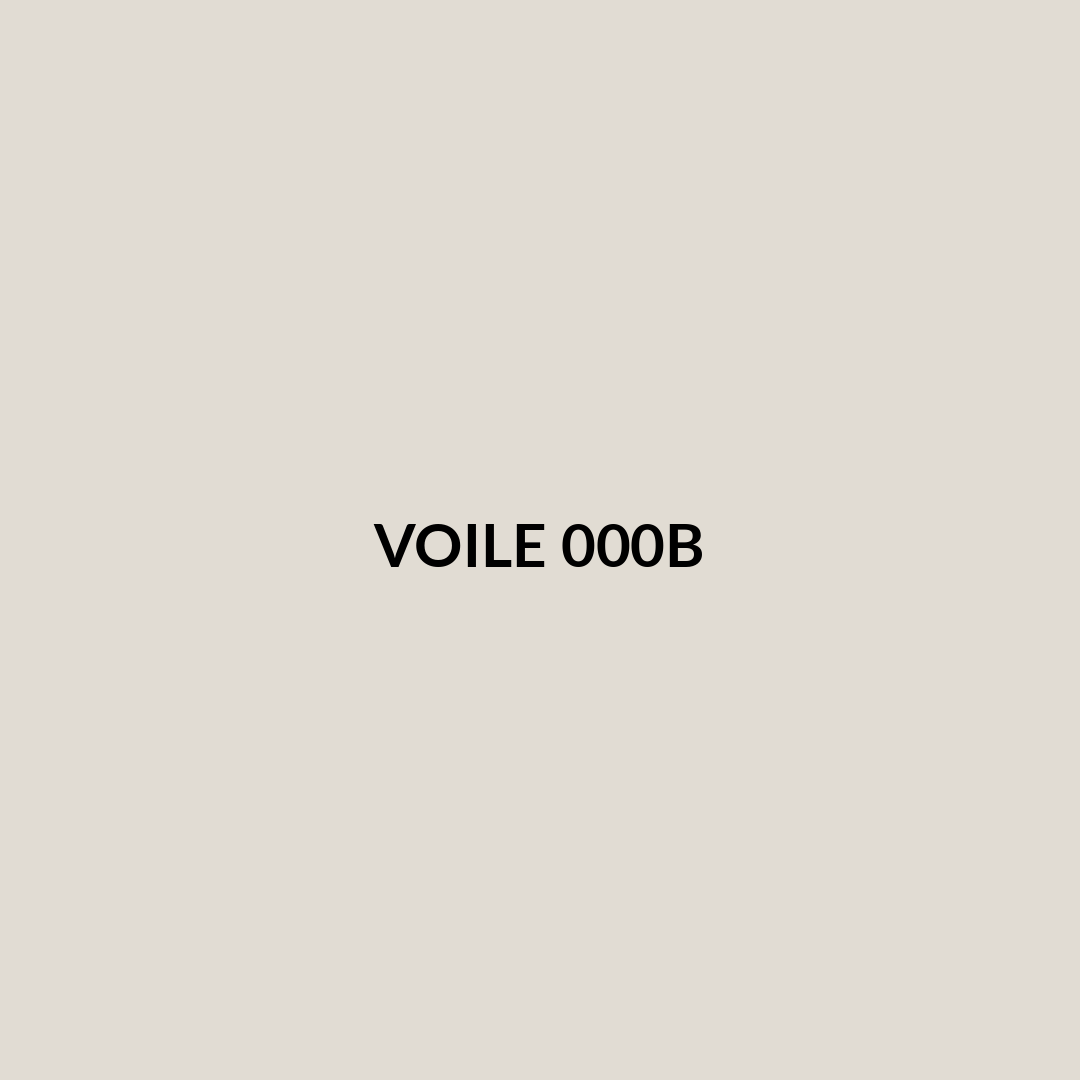

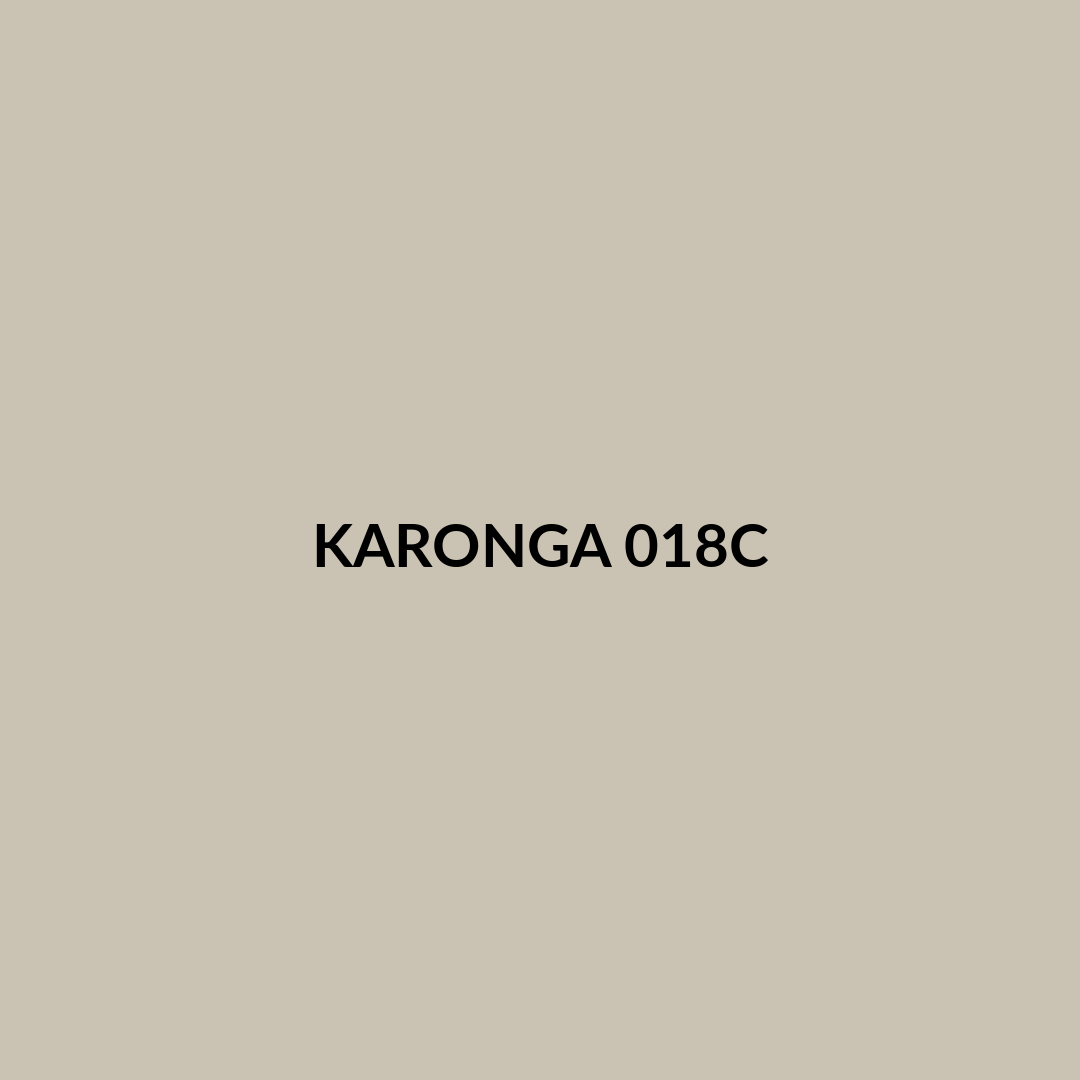

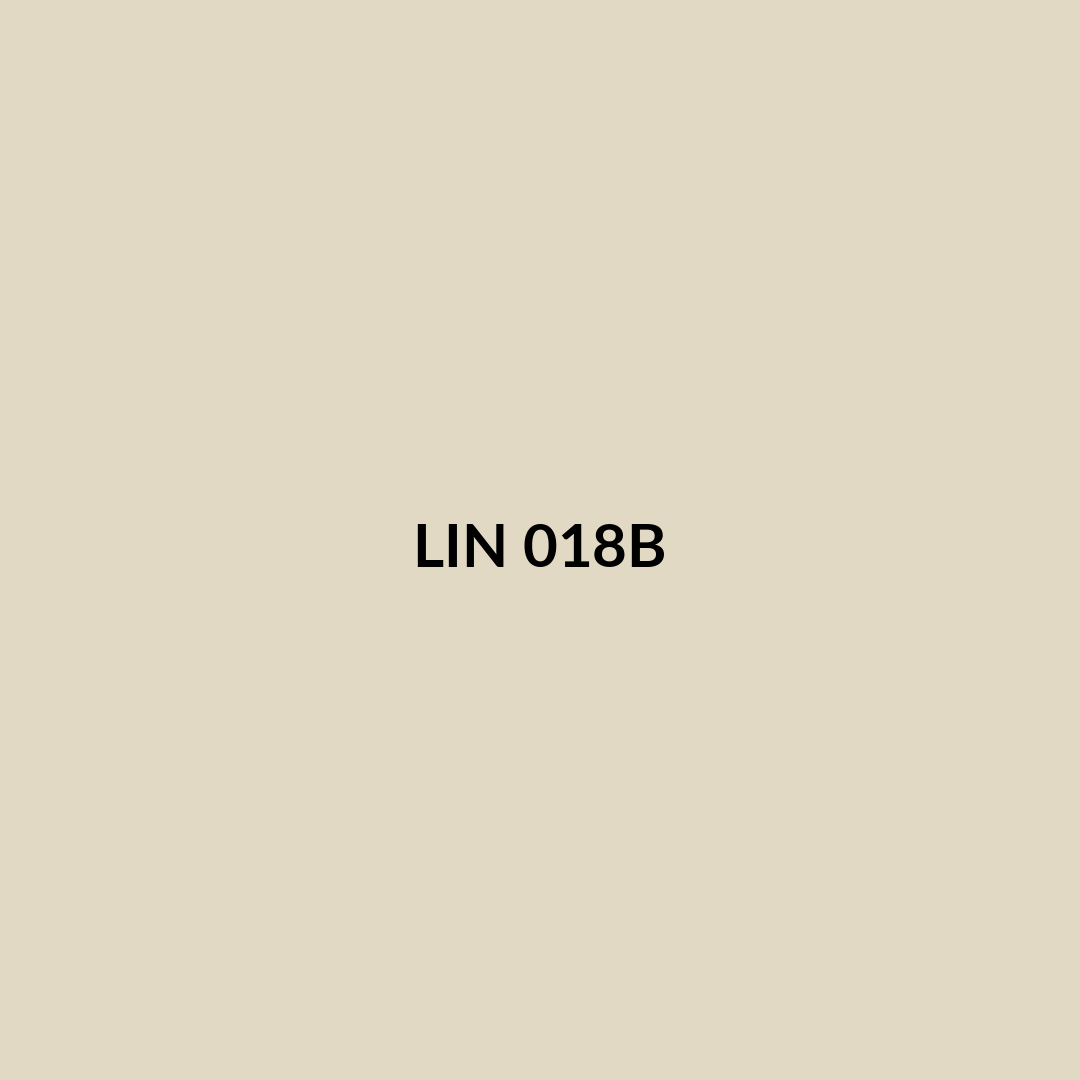

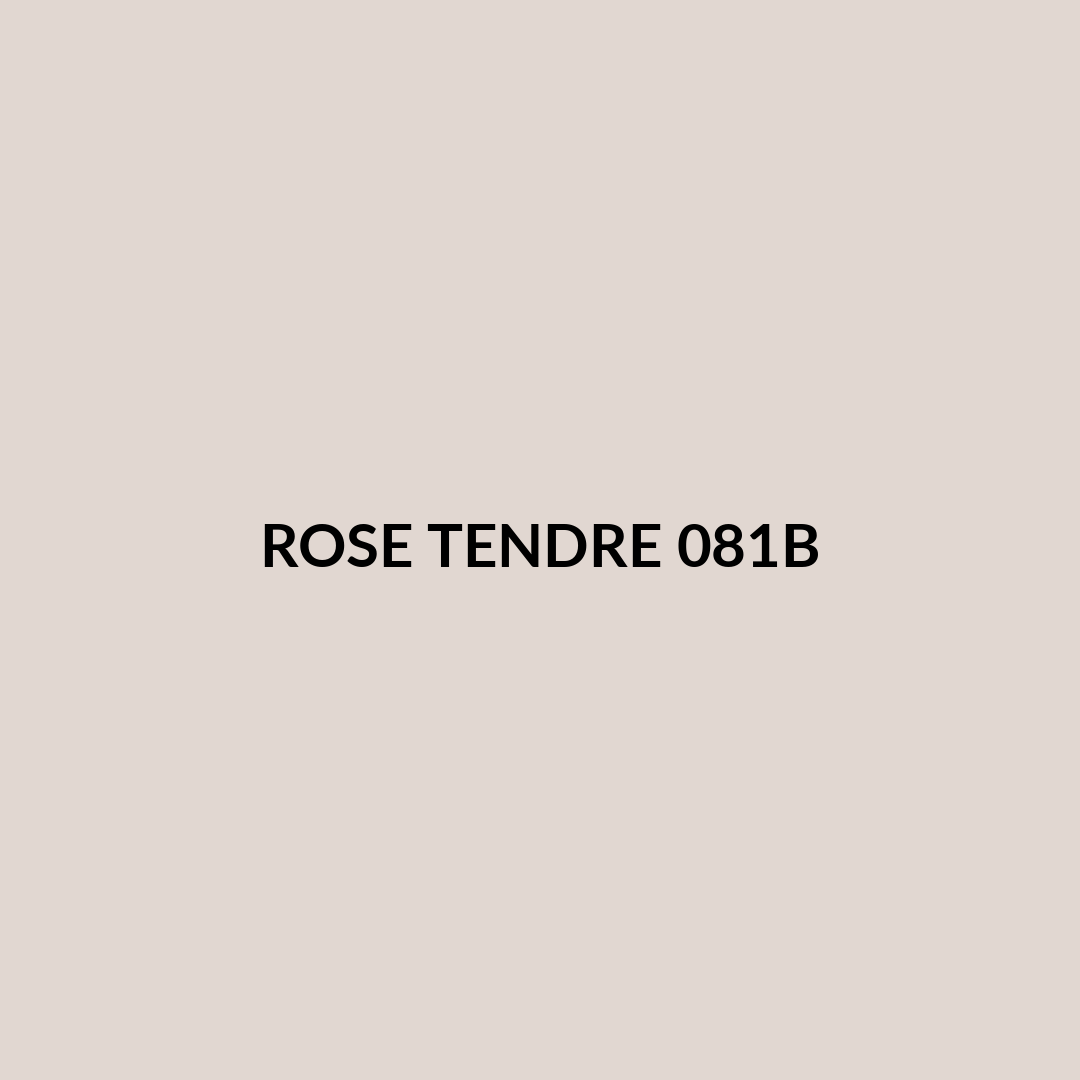

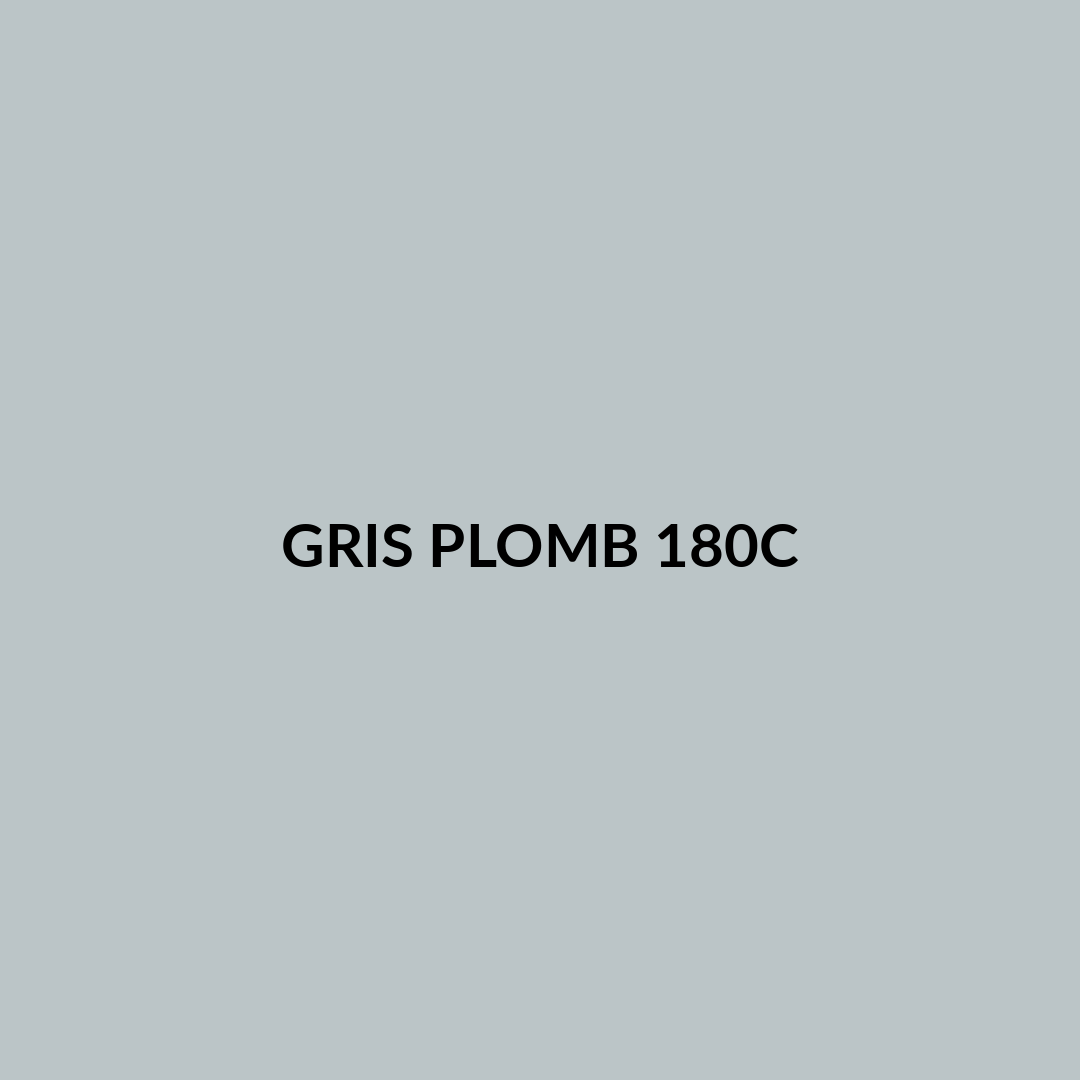

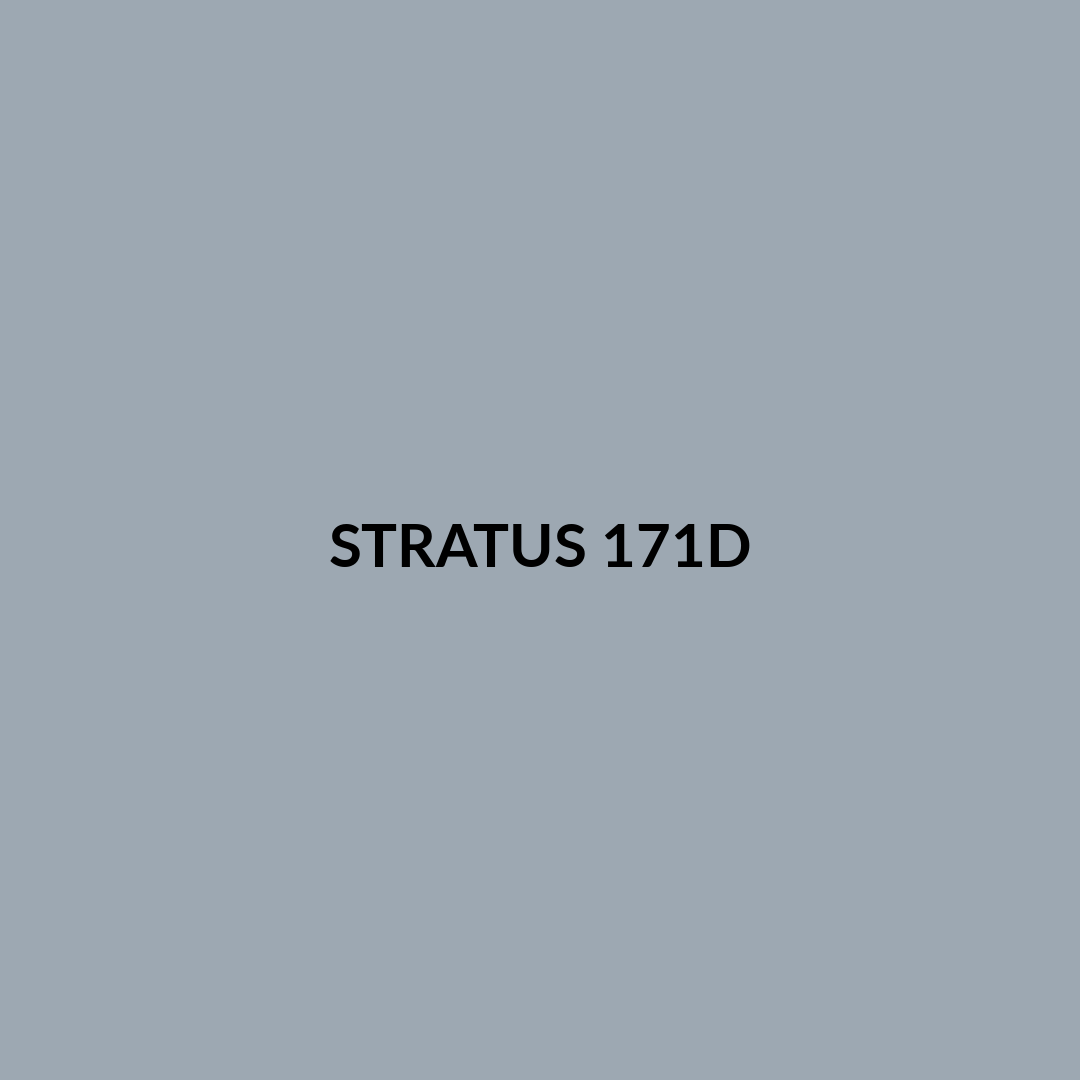

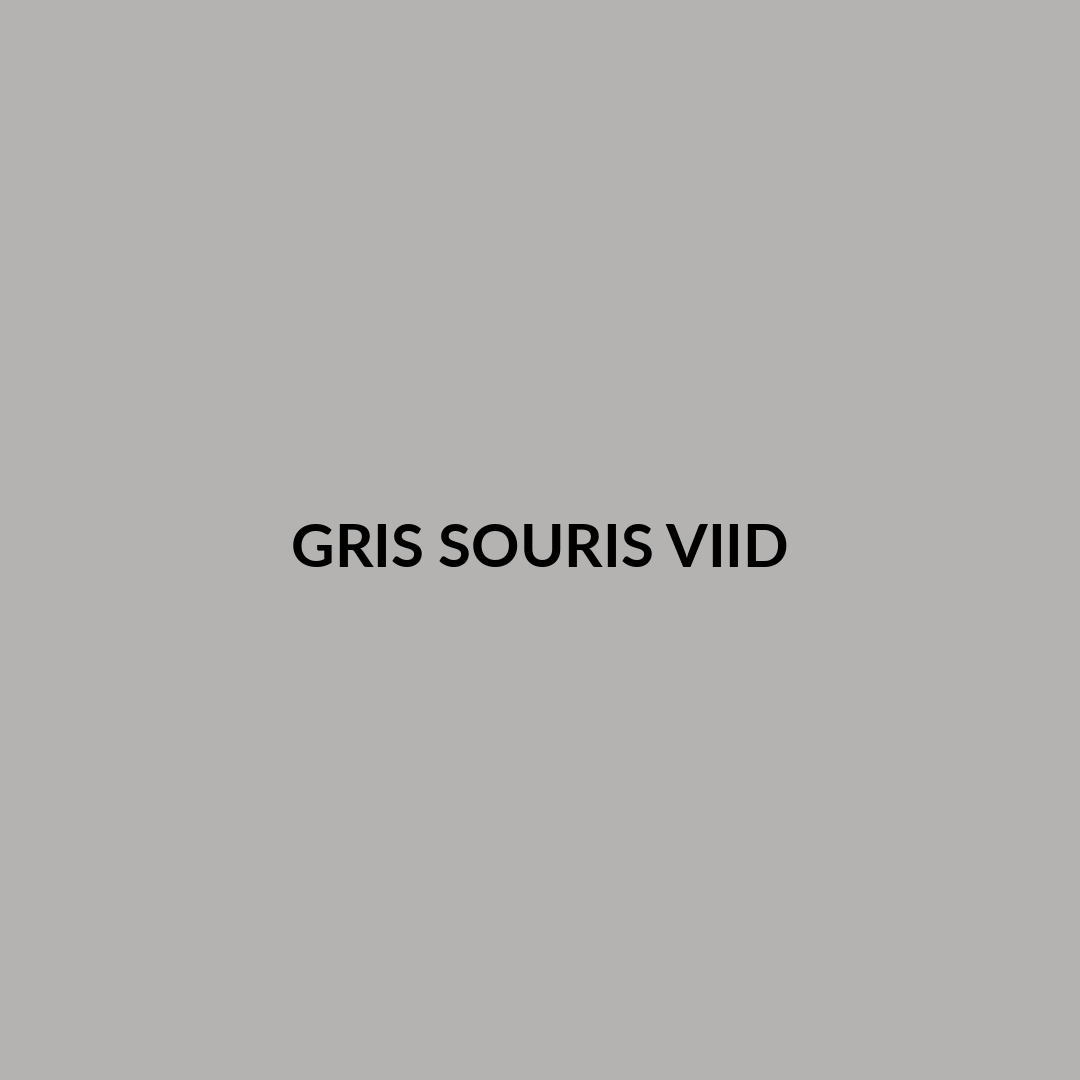

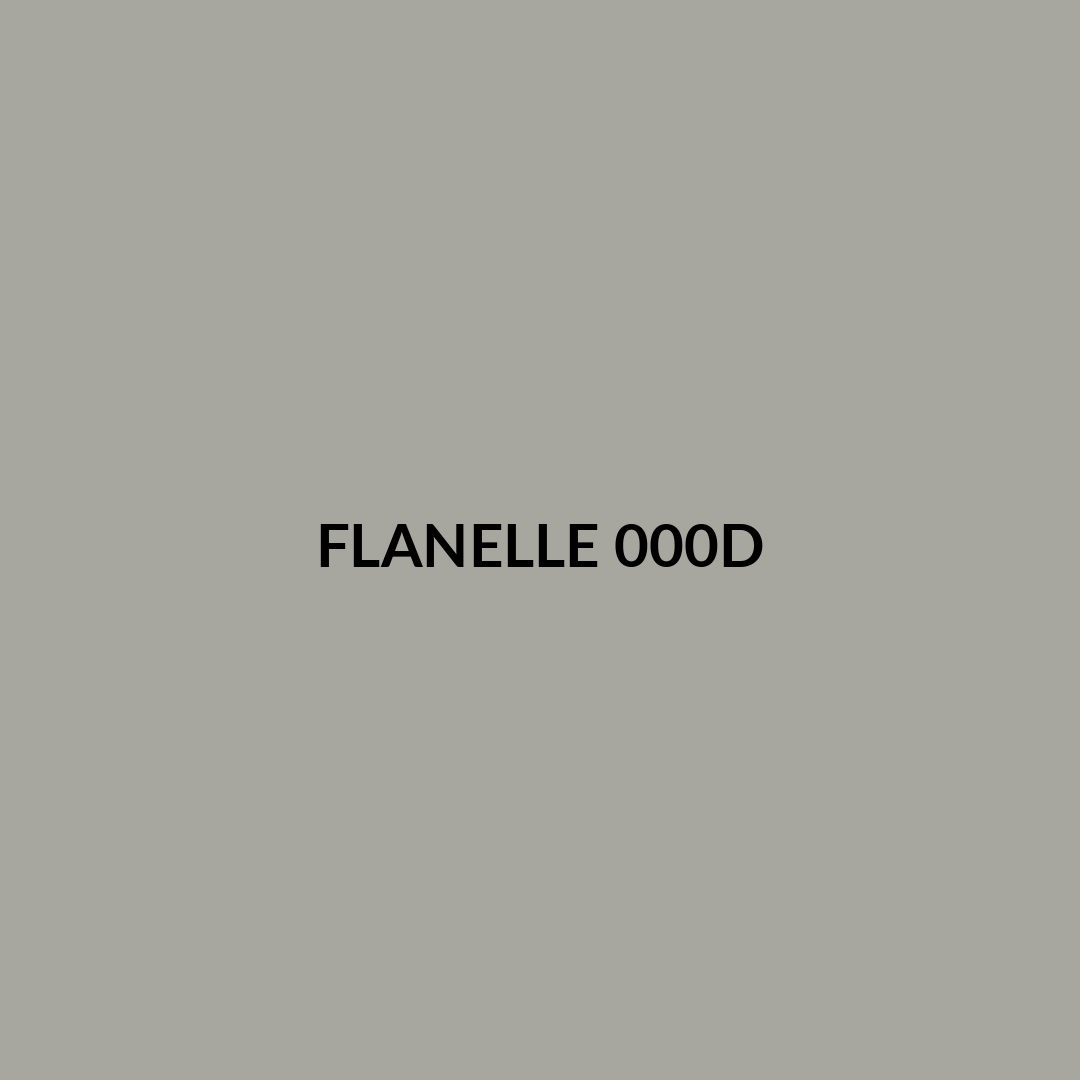

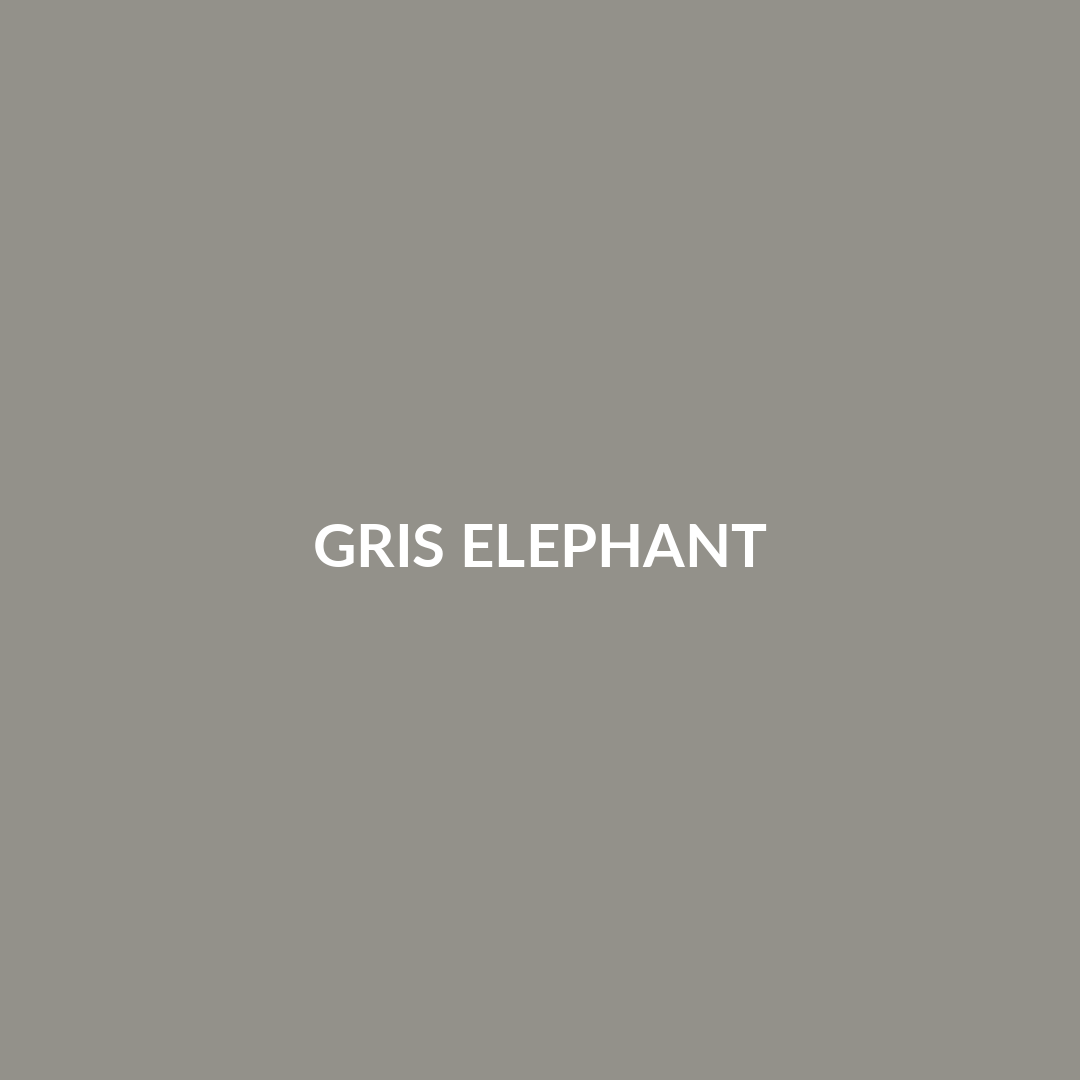

Color chart for the BFHP Marius Aurenti

Technical data sheets (PDF version)

Technical sheets (web version)

07/03/2023 edition

Presentation

AREAS OF USE

A product designed to facilitate the demolding of cast, fiber-reinforced Smart’up design concrete.

COMPOSITION

Aqueous-phase lubricant suspension

PROPERTIES

Odorless, non-toxic release agent specially formulated to minimize bubbling, staining, chalking and clinging. It gives a light, uniform shade to formwork-free concrete. It’s environmentally friendly. It’s easy to use and can be rinsed with water.

PACKAGING

1 L

Implementation

Composed of 2 phases (oil and water), it is essential to homogenize the release agent before use.

APPLICATION EQUIPMENT

Clean, dry, lint-free cloth, pressure sprayer (minimum 1 bar) or airless spray gun

CONDITIONS OF APPLICATION

Suitable for many types of molds (polyurethane, treated wood, metal, composite). We recommend that you carry out a trial run beforehand, depending on the mold in question.

APPLICATION METHOD

For small surfaces, apply by hand with a clean, dry, lint-free cloth. Spread the release agent evenly in the mould and wipe off any excess.

For larger surfaces, use a pressure sprayer (minimum 1 bar) or an airless gun with a very low flow rate.

CONSUMPTION

30 to 60 m²/litre

TOOL CLEANING

Equipment should be cleaned with water after use.

Technical specifications and performance 4

PRODUCT APPEARANCE

White opaque liquid

DENSITY A + B (AT 20°C)

0.9 g/cm3

STORAGE AND SAFETY

1 year in original, unopened packaging, out of direct sunlight and frost, at temperatures between +5° and 35°C.

For further safety information, please consult the Safety Data Sheet.

Warning

Designed, developed and manufactured in France. All data presented in this Technical Data Sheet are provided for information purposes only and do not engage our responsibility. Under no circumstances should they be construed as a warranty. Testing is necessary. This data sheet is subject to change, so please check that it is the latest edition. This data sheet cancels and replaces all previous versions. Furthermore, as the implementation and conditions of application are not under our control, we decline all responsibility. For further information on precautions for use and safety instructions, please contact our Marius Aurenti teams.