Marius AurentiMicrocement

Why choose Marius Aurenti Microcement?

For over 40 years, Marius Aurenti has been developing high-performance decorative microcement, serving both architecture and craftsmanship. Our expertise is built on unique know-how, French manufacturing, and tailored support for every project.

A responsible and controlled manufacturing

At our sites in Châteauneuf-sur-Isère and Romans-sur-Isère, Marius Aurenti produces its made-in-France microcement using primarily local materials. This commitment has earned us a leading position in the market and a commercial presence in over 20 countries. Discover the environmental commitments of Marius Aurenti.

The 7 advantages of Marius Aurenti Microcement

Microcement FAQ

However, for a flawless, long-lasting finish with no surprises, we recommend working with a qualified professional. Their expertise ensures a stress-free application, especially on technical or high-traffic surfaces.

Contact an advisor to find a skilled artisan or request a free quote.

There’s no need to remove the existing tile — microcement can be applied directly on top in just 2 to 3 mm (0.08″ to 0.12″) of thickness. This innovative solution, used daily for over 20 years, allows you to modernize your space while increasing the value of your home.

Thanks to its minimal thickness, there’s no change in floor levels between rooms, no need for transition strips between materials, and no adjustments required to door heights — a major advantage, especially for exterior doors where modification is often impossible.

This is one of the key strengths of Marius Aurenti’s millimetric microcement. Refer to our dedicated section on microcement over tile to explore the technical details and application methods used by professionals.

Within this palette, Marius Aurenti offers 71 mineral microcement colors to meet every aesthetic need. Finely ground mineral pigments reflect light with exceptional depth and long-lasting UV stability.

Our distributors and showrooms present these shades in person and through samples to help guide your design choices. To support your decision-making, both color charts and physical samples can be ordered from the materials library or viewed online (depending on screen calibration).

Trusted for high-end design projects, Marius Aurenti also works with architects and color specialists to develop custom shades in our lab for truly tailored creations.

For project-specific details and an accurate estimate, we invite you to request a free quote. Our experts will be happy to guide you through your project.

You can trust in the strength and long-term performance of our microcement solutions.

In rare cases, the impact may cause a chip in the surface. A local microcement application can be considered. To avoid a "patch" effect, a tinted product—such as a repair cream or mineral stain—can be used to effectively blend and conceal the repair.

To deep clean dirty surfaces, apply the Multi-Purpose Degreasing Cleaner diluted to 10%, one to three times per year, and rinse with water. A soft brush can be used to clean the pores of the microcement.

Depending on the type of protection originally applied, here’s how to renovate it:

- Microcement floor with wax: About every 5 years (depending on the desired finish and the patina of the floor), strip the surface using MA’s Wax Remover. Once the surface is clean and dry, apply High-Resistance Wax in 2 coats.

- Microcement surface with varnish (floor, shower, countertop): Every 5 to 15 years (depending on wear), clean using the Multi-Purpose Degreasing Cleaner diluted to 10%, then rinse with water. Lightly sand the surface with a floor buffer or orbital sander (grit 120 or higher), remove dust, and apply 2 new coats of varnish.

- Outdoor microcement floor (terrace): Every 2 to 5 years, clean using the Multi-Purpose Degreasing Cleaner diluted to 10%, then rinse with water. Once dry, apply 2 coats of Terrace Impregnator No. 2.

First, application requires precision and respect for drying times. While ready-to-use kits greatly simplify the process, proper technique—or the involvement of a professional—is still recommended to ensure a smooth, long-lasting result.

Second, microcement is an ultra-thin coating: it must be applied over a stable, clean, and well-prepared surface. On cracked or damp substrates, special precautions are necessary.

Lastly, as a mineral material, it evolves over time. Fine microcracks may appear if application protocols are not followed or if the substrate undergoes unusual movement.

However, when properly applied, microcement delivers a unique, warm, and timeless finish with durability suited to many uses—from bathroom floors to kitchen backsplashes.

Marius Aurenti products are backed by a 15-year crack-free guarantee, thanks to over 40 years of expertise and unmatched craftsmanship in the industry.

Marius Aurenti products come with a 15-year crack-free guarantee, supported by over 40 years of expertise and a unique level of craftsmanship in the industry.

Microcement does not crack without cause. When a crack appears, it is often the result of movement in the substrate. Microcement, applied in a thin layer (about 2 to 3mm (0.08″ to 0.12″)), follows the behavior of the surface it is applied to. If that surface moves, shifts, or has structural issues, microcracks may appear.

Another common cause is the failure to follow preparation steps: unstable substrate, missing primer, or lack of treatment for expansion joints. It is essential to apply microcement on a sound, clean, and suitable base.

When applied according to best practices, using high-performance technical products on a properly prepared surface, microcement remains stable and durable over time. This is why it is recommended to work with a qualified professional or to follow the technical guidelines closely during application.

Technical datasheets (PDF version)

Testing & hardness measurement of Marius Aurenti Microcement

Compressive strength test

Marius Aurenti Microcement offers outstanding compressive strength of 44 MPa (6,400 psi), certified by CSTB testing.

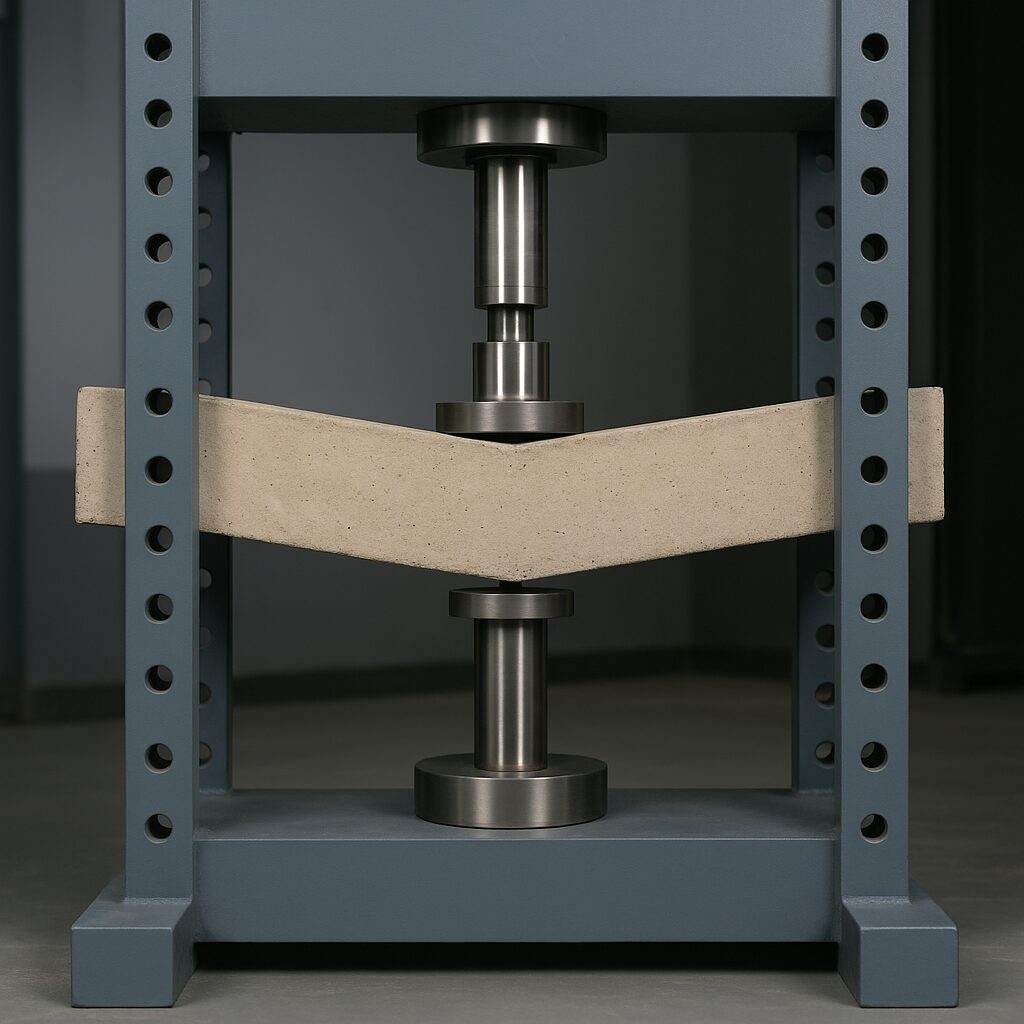

Flexural strength test

Marius Aurenti microcement achieves a flexural strength of 16.8 MPa (≈2,436 psi), meeting the standards of CSTB testing.

Hardness measurement

The surface hardness of Marius Aurenti microcement reaches 119.1 N/mm² (≈17,280 psi), certified by CSTB testing, ensuring excellent resistance.